HVAC surge protectors utilize fast response times (less than 5 nanoseconds) and strong grounding to protect your system from voltage spikes, ensuring efficient operation.

Introduction to HVAC Surge Protectors

Every building needs an effective heating, ventilation, and air conditioning (HVAC) system to keep the occupants comfortable and able to breathe properly. However, power surges can damage them. This popular HVAC surge protector is a must-have to prevent these systems from being damaged by power surges, thereby extending their operating time and improving their performance.

What a Surge Protector Does

HVAC surge protectors include surge protectors, which are one of the important components of surge protection. It is a protective layer between the HVAC and the incoming power surge. If a power surge occurs, the device transfers the overvoltage around the HVAC system in a fraction of a second, keeping it safe from damage. If you want your HVAC system to be properly protected from power surges, then you should consider buying a high-quality surge protector that can withstand thousands of volts of surge.

Voltage Clamps

Reducing the voltage level coming into the HVAC system is a very important part of the voltage domain. This way the voltage stays within a safe range. For example, if the normal operating voltage of the HVAC system is 240 volts, the voltage clamp will trip when the voltage exceeds this level, reducing it to a safe level. This is because you need to avoid overvoltage and excessive damage to the flammable components of your HVAC system.

Importance of Grounding System

For HVAC surge protectors to operate safely, they require a properly functioning grounding system. This allows excessive voltage to pass through it and into the ground, and the grounding system acts like a 0 ohm resistor between two conductors, which is considered ideal if it is implanted. Unfortunately, without a stable grounding system, the HVAC system cannot be properly grounded and the surge protector cannot function properly, thus failing to provide this protection. It is imperative to ensure that your grounding system is up to code and working as required to protect your HVAC system.

How Filtering Mechanisms Work

HVAC surge protectors include filtering mechanisms that help eliminate noise or minor fluctuations in voltage. Fluctuations in thermostat settings can damage the HVAC over time. This filtering mechanism blocks these small surges and spikes, providing clean and stable power to the HVAC system. Not only does it help save the device, but it also helps improve the efficiency and performance of the device.

Response Time and Its Impact

Response time is how quickly the surge protector responds to a surge. The response time must be fast, so the device can react quickly when the HVAC system is exposed to voltages high enough to damage the system. Fast response: The best surge protectors have response times measured in nanoseconds, which means they can be triggered to shut down in almost no time. Surge protectors with response times under 1 nanosecond provide the best protection in the long run than those with slower response times.

The Role of the Surge Protection Device

Power surges can be protected by surge protection devices (SPDs), which are critical to HVAC systems. Some also use surge protection devices or lightning arresters as a first level of defense to absorb and shunt any overvoltage conditions, preventing them from affecting sensitive components. Let’s dive into the theoretical aspects of the functions and relevance of these devices.

Absorbing Overvoltage

Essentially, SPDs are designed to handle voltage spikes that exceed the normal operating parameters of an HVAC system. For example, if the HVAC system operates at 240 volts, the surge protection will spring into action when the line voltage rises to 300 volts or more. This quick response helps prevent internal burnouts from momentary spikes.

Redirecting Surges to Ground

SPDs are designed to redirect surges from an HVAC system to a grounding system. This approach prevents excess current from entering your house, using a ground wire to direct it to the ground where it can be safely dissipated. Having a strong and effective grounding system is essential so that surge energy can be drained away from the system, preventing potential damage. This measure is especially important during extremely severe weather conditions, such as thunderstorms that can cause large surges.

Components Inside an SPD

There are many components inside an SPD, and while they may vary, they typically include Metal Oxide Varistors (MOVs), Gas Discharge Tubes, and Diodes. MOVs – As the most common protective devices found in PCB assemblies, they will clamp any high voltage levels. They are able to absorb a large amount of electrical energy and convert it into heat. For example, MOVs are able to handle surges of up to 6,000 volts and discharge currents of up to 20,000 amps to fully protect an HVAC system.

Response Time of an SPD

The effectiveness of how quickly an SPD reacts to an increase in current or voltage is very important. This reduces the likelihood that the HVAC system will be exposed to harmful voltage levels. A high-quality SPD can function in a time that is usually measured in nanoseconds. For example, a response time of 5 nanoseconds is much faster than a response time of 20 nanoseconds, which means better protection.

Durability and Lifespan

The durability of an SPD is another factor that affects its effectiveness. In contrast, good models are designed to survive multiple surges in their lifetime – only the most ineffective models will experience performance degradation. The lifespan of a good SPD is between 3-5 years on average, depending on the surges it is subjected to, beyond which point they not only cease to function, but as an added risk, are more likely to catch fire when faced with greater overloads. It is highly recommended that this device be inspected regularly and serviced monthly to keep it in perfect condition.

Installation and Maintenance

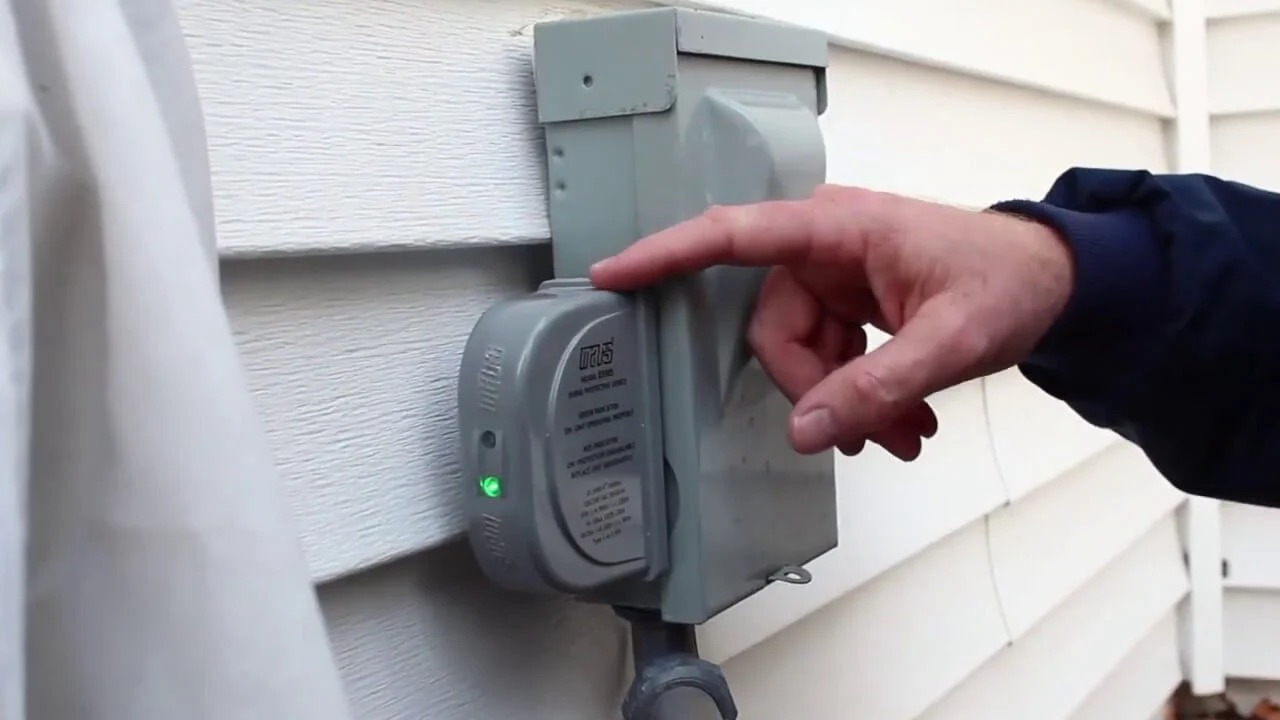

Proper installation of SPDs is critical to protecting the system. They should be located close to the HVAC system power source to reduce the surge energy path. It is also important to perform routine maintenance checks to verify that all parts of the sprinkler system are functioning properly and that the grounding system is in place. It can provide advance warning of surges to machinery and allow the device to surge protect any equipment within the affected area, allowing the device to protect the facility and safeguard equipment where traditional surge protection would not normally be installed. This does not replace the need for surge protection on the equipment, but is in addition to the standard surge protection on the equipment.

Understanding the Voltage Clamp

Voltage clamps are an essential part of HVAC surge protectors that help protect your heating, ventilation and air conditioning (HVAC) system, keeping it controlled and safe. It ensures that the voltage always stays within a safe range, so you can rest assured that a surge could burn out your entire system. Voltage Clamp Overview: What is a Voltage Clamp and How It Works

What a Voltage Clamp Does

The main function of a voltage clamp is to control the voltage coming into your HVAC system. When the voltage is above a certain safe point, the voltage clamp will engage and attenuate the voltage to a safe voltage. For example, if your HVAC unit requires 240 volts to operate, if the voltage rises to 260 volts, the voltage clamp will trigger another path to reduce the voltage to a safe level.

Mechanism of Operation

Usually the voltage clamp switches a metal oxide varistor (MOV) for this purpose. In simple terms, MOVs are silicon LDRs, except they are a faster type with a resistance that changes with voltage levels. In normal operation, MOVs do not conduct electricity and current can flow unimpeded. But when a spike occurs, the resistance of the MOV drops dramatically, shunting the excess voltage away from the HVAC equipment. This reaction time, in turn, prevents damage to the delicate parts of your dryer.

Voltage Clamp Performance Example

Let’s say a bolt of lightning strikes your house and sends a 4,000-volt surge. If you were to predict whether this surge would damage your HVAC system, imagine what it would look like without a voltage clamp. The MOV absorbs the surge, while the efficient voltage clamp ensures that the excess voltage is redirected, keeping the system’s voltage within safe levels. This quick step can prevent breakdowns and costly repairs.

Benefits of Voltage Clamping

The introduction of voltage spikes is absorbed, further extending the life of your HVAC. Second, it stabilizes the voltage to ensure consistent performance. This stability is essential for HVAC system operation; voltage variations can cause inefficiencies and put additional stress on all associated equipment, either shortening its life or damaging it outright.

Durability and Maintenance

Voltage clamps are designed to last for long periods of time. Many quality voltage clamps can withstand several surges before they begin to degrade. Schedule regular maintenance and keep a close eye on the clamp to ensure it is functioning properly. The MOVs in the clamp will naturally weaken over time, especially in areas with more surges, so it’s important to inspect them regularly.

Installation Considerations

Please understand the meaning of properly installing voltage clamps. They should be installed on the condensing unit as close as possible to the power entry point of the HVAC system to keep the surge propagation distance shorter. It allows for faster response time and greater data security. In addition, ensuring that the grounding system is strong and working properly supports the overall functionality of the voltage clamp.

The Importance of the Grounding System

This is very important because without a grounding system, overvoltage will safely block sensitive equipment. The effectiveness of the entire surge protection system depends largely on the quality of grounding. Here is an in-depth introduction to the topic of grounding and what it means.

Role of Grounding System

A safe path for excess electrical energy to be released or discharged to the ground. The grounding system transfers the surge to the ground when the spike comes from lightning, power lines, and when the surge is generated inside the system, the system transfers the additional voltage associated with the connected equipment and HVAC system to the ground. It suppresses the presence of dangerous voltage levels that can harm the equipment.

Components of Grounding System

Main elements of a typical grounding system:

- Grounding rod: A metal rod inserted into the ground that serves as a quick path for electrical energy to escape.

- Grounding wire: A wire that carries power between the HVAC system and the surge protector and between two grounding rods.

- Busbars: These are the common points where all grounding wires are connected together to form a common ground point, i.e. a common grounding system.

Proper installation and maintenance of each component is a must for ideal performance. A poorly installed grounding system is effectively the same as having no grounding system at all (e.g. ground rods driven to the wrong depth or into non-conductive soil).

Installation Best Practices

It is critical that a grounding system is properly installed. Ground rods should be buried at least 8 feet into the ground to get a good ground connection. Soil conditions can also vary as moist, clay-rich soils are more conductive than dry, sandy soils; ground wires should be large enough to better manage the current during surges, so at least 6 AWG (American Wire Gauge)

Performance and Safety

After grounding, the ability of the grounding process to be grounded can be measured. A properly installed grounding system should have a ground resistance of less than 5 ohms. Because of the low resistance here, surge energy will be discharged through it very effectively. It is recommended to periodically check the ground with a ground resistance meter to ensure that the system resistance remains within this optimal operating range.

Impact on Protecting HVAC Systems

A strong grounding system improves the protection of the entire HVAC system. Additionally, even the best surge protector will not work if it is not properly grounded, as a surge protector without an effective ground path means that the excess voltage has nowhere to go. This can force surge power to bounce back into the system, potentially damaging sensitive components such as compressors and control boards.

Maintenance and Inspection

Regular maintenance and inspection of the grounding system is required to ensure good grounding system performance. Inspect ground connections annually to ensure they are secure and clean. Because soil can become unstable with changing environmental conditions and the conductivity of ground rods can change over time, regular testing and corrective actions should be performed to ensure the durability of the grounding system.

How the Filtering Mechanism Functions

HVAC surge protectors also act as a filtering mechanism, allowing the mechanism to operate smoothly. This ensures that minor voltage variations and electrical noise that could affect the performance or life of the system are reduced. Below is a detailed description of this system and its importance.

Why Filtering Mechanism is Needed

The filtering mechanism is primarily responsible for removing minor variations in voltage around the vehicle, as well as electrical noise. This is called "electrical noise" or "transient noise" and can come from a variety of sources, including other electrical appliances, industrial equipment, and even the Heating, Ventilation and Air Conditioning (HVAC) system itself. This allows the mechanism to filter out this distortion and guarantee a steady, clean supply of energy to the HVAC system, allowing it to operate efficiently without interruption.

The filtering mechanism occurs in the following components.

A typical filter usually involves several important parts:

- Capacitors: Store and release electrical energy, providing a steady flow of voltage.

- Inductors: They create a magnetic field to resist changes in current, acting as a filter for high-frequency noise.

- Circuit breakers: They release electrical energy, dissipate it as heat to reduce noise, and ensure that the voltage is always stable.

All of these components work together to block unwanted electrical interference. For example, capacitors absorb voltage spikes, while inductors block high-frequency noise, allowing clean, stable voltage to enter the HVAC equipment.

How it works (Filtering Mode)

In the presence of electrical noise or small fluctuations in voltage levels, filtering mechanisms are triggered to attenuate these disturbances. These capacitors temporarily store unused energy and release it to stabilize the voltage when it drops. Conversely, inductors actually slow down these rapid current changes, preventing high-frequency noise from passing through. So when these actions are done together, they provide a continuous and stable power supply to the environment, which reduces the level of wear and tear on HVAC components.

Why Filtering in HVAC Systems?

Filtering electrical noise and voltage fluctuations is critical because:

- Improved performance: Stable power allows the HVAC system to operate as efficiently as possible, resulting in optimal heating and cooling performance.

- Extended life: Filtering systems allow the HVAC system to put less electrical stress on its components, which means a longer overall life in the end.

- Reduced operating costs: Reduced wear and tear, less expansion, contraction noise reduces future failures, thereby reducing maintenance and repair costs.

Take HVAC systems as an example — HVAC systems with high-efficiency filtration systems can run 20% more efficiently over their operating time and have 15% lower maintenance costs.

Installation and Ongoing Filtration System Maintenance

It is absolutely necessary to keep the filtration mechanism working properly if the correct installation guidelines are followed, and to continue it as regular maintenance. Capacitors and inductors need to be placed close to the power entry point of the HVAC system to gain their maximum benefit. They need to be checked regularly to look for any wear and tear. For example, capacitors can "dry up" and lose the ability to store and release energy, while inductors can experience insulation breakdown.

The Impact of the Response Time

One of the most important attributes of how well an HVAC surge protector works is its response time. Basically, this refers to the time it takes for the entire house unit to react to an overload—which is key to helping protect HVAC system components from harm. This infographic takes a closer look at how response time plays a big role in surge protector performance.

Definition and Importance of Response Time

Response time is the time it takes for the circuit breaker in a surge protector to react to a surge. This metric measures the time span it takes for a device to detect and resolve a spike in power flow, measured in nanoseconds (ns). The faster the response time, the less time the HVAC system is exposed to dangerous voltage levels. A shorter response time means the surge protector can respond faster to the power lines, providing better protection, with a 1 ns response time being better than a 20 ns response time, for example.

How Response Time Works

A surge protector has only milliseconds to detect and respond to a surge. It uses sensors to provide real-time updates on voltage. When a spike is detected, the sensor instantly activates the protection element, quickly clamping the overvoltage and moving it out of the HVAC system. This is of course important for preventing damage caused by surges.

Measuring Response Time Efficiency

To intuitively understand the importance of response time, consider this: 10 nanoseconds – the duration of a spike caused by lightning. If the surge protector is, for example, an HVAC surge protector with a response time of 1 nanosecond (one billionth of a second), it will activate within the first nanosecond and leave 9 nanoseconds of exposure time. Meanwhile, a product with a response time of 20 nanoseconds will not activate until after the voltage spike has already done its damaging work, and the voltage could theoretically have increased by 500,000,000% before then. This is one reason why it is critical to select a surge protector with a very fast response time.

Advantages of Fast Response Time

- Enhanced Protection: Faster response times prevent surges from causing surge-related damage to HVAC system components while minimizing the risk of damage.

- Extended Equipment Life: By virtually reducing surge exposure, HVAC system components will experience less electrical stress, resulting in a longer life.

- Reduced Downtime: Fast response time means less potential damage and fewer potential causes for system failure, which helps ensure your HVAC system continues to operate even after a surge event.

The 5 ns transient mode suppression category is critical, as studies have shown that HVAC systems equipped with surge protectors with response times below 5 ns experience up to 50% more surge-related field failures.

Advances in Response Time Technology

New-age surge protectors are designed with more advanced features and faster response times. Metal oxide varistors (MOVs) and silicon avalanche diodes (SADs) are used for fast response. These devices can react to voltage spikes in the sub-nanosecond range, providing instant protection.

Choosing the Right Surge Protector

As the primary feature of an HVAC surge protector, look for options with a delay time of 5 nanoseconds or less. You’ll also want to verify that the surge protector is rated for the right voltage and current levels for your HVAC system output (to ensure proper protection).

Maintenance and Monitoring

In addition, it’s important to maintain and monitor it regularly so that it can respond quickly. Inspection: Protection components can be inspected for wear or other forms of degradation and replaced if needed. Some modern surge protectors have integrated monitoring systems that notify you when the protector stops working, letting you know it is not functioning properly and informing you to replace it for further protection.