The best DC MCBs feature arc fault detection, ground fault protection, and a modular design for easy installation, reducing setup times by up to 50%.

Understanding DC MCB Technology

DC Miniature Circuit Breakers (MCBs) are essential for overcurrent control and preventing circuit contamination, which can lead to overcurrent damage from overloads or short circuits. The technology is designed to provide safety and efficiency to electrical systems, especially in low-voltage DC applications such as solar systems, battery management systems, and automotive solutions.

How DC Miniature Circuit Breakers Work

MCBs work by sensing overcurrent and mechanically opening the circuit to stop possible damage. Unlike AC circuit breakers, they cannot extinguish arcs generated by current interruption in DC circuits. In DC circuits, the current has no natural zero point, so breaking the circuit is more difficult and requires a more specialized approach.

Components and Materials

DC Miniature Circuit Breakers are made of rugged materials to withstand the challenges of DC power supplies. The contacts are typically silver alloys that resist corrosion and fire, while the body is a molded insulating material surface with high thermal resistance and strength to prevent arcing between contacts or other metallized parts without the need for additional insulation from the open air.

Key Technologies Involved

Magnetic circuit breakers are one of the main technologies for DC miniature circuit breakers, which utilize solenoids to provide the power required for circuit interruption. Thermal mechanisms are also prevalent, relying on a bimetallic element that bends when heated by excessive current limiting the circuit breaker.

Latest Innovations

In recent years, we have seen the development of DC miniature circuit breakers based on the integration of electronic sensing elements that allow for more precise control of the tripping mechanism. They are also fault type observation systems that can identify the type of fault in the line current and improve the safety of the miniature circuit breakers. Today, manufacturers tend to design systems that can be remotely monitored and provide real-time data analysis or system management features that can have a significant impact on the reliability and efficiency of the system.

Comparative Efficiency

DC Miniature Circuit Breakers: DC Miniature Circuit Breakers (MCBs) are highly efficient in terms of minimum power loss. Well, this is important for battery-powered systems, where every watt is precious. For example, in solar power generation systems, DC MCBs not only help ensure that the power is managed safely, but also that it is not wasted.

Market Adoption and Feedback

Feedback from users all confirms the fact that when using modern DC MCBs, they provide better safety and are very reliable. According to market research, the adoption rate of renewable energy deployment continues to increase, with deployment rates growing by more than 25% over the past five years, indicating a growing confidence and reliance on these devices in mission-critical installations.

Enhanced Safety Features

DC Miniature Circuit Breakers (MCBs) are specifically designed to provide a safe method of protecting electrical circuits as well as users and the environment. Alternatively, the best DC Miniature Circuit Breakers can include a range of improved safety measures that greatly reduce the likelihood of electrical fires and other accidents.

Arc Fault Detection

Arc fault detection technology is one of the most important safety improvements in modern DC Miniature Circuit Breakers. It enables the circuit breaker to verify arc conditions, which are a common precursor to electrical fires. These devices are one of the safest single points of failure to reduce the risk of electrical fires in DC circuits, identifying and interrupting unstable arcs, which can account for up to 75% of most (ground) arcs. It has been reported that electrical fires can be reduced by more than 50% using arc fault protection devices.

Ground Fault Protection

The top DC Miniature Circuit Breakers feature integrated ground fault protection. This mechanism is specifically designed to detect lethal leaks of small currents that can be life-threatening, in other words, potential risks to humans, especially in humid environments, where they could be electrocuted or at risk of fire. When the current level exceeds a certain threshold (usually 30 mA), the MCB immediately disconnects the circuit where this occurs to prevent the potential dangers caused by the ground fault.

Thermal Overload Protection

An example of how thermal protection in a DC MCB works is that when the current in the circuit is above a certain value (i.e. overcurrent), the bimetallic strip heats up and arches, triggering the MCB to trip. This makes Operating Breaker Corporation a very simple mechanism, but its simplicity often prevents overheating from causing potential insulation damage or sparks that start fires. TCI precision thermal sensor technology in modern MCBs enables them to quickly detect small overloads, protecting the electrical system and the environment.

Circuit Isolation Functionality

When tripped, they ensure complete circuit isolation, preventing any residual current from causing shock or malfunctioning other devices in the circuit and their controllers. This feature is particularly useful in maintenance scenarios where safe access to electrical components is required.

User-Friendly Interface

The control relays in many current DC MCBs use a user-friendly interface meaning that they are clearly labeled with minimal status indicators, supplemented by powerful manual commands. This makes it the perfect item for professionals and laymen to handle when working on their own electrical systems. A good interface makes the equipment safer because the possibility of improper use or misreading the status of the equipment is reduced.

Comply with international safety norms

The best DC MCB brands adhere to international safety standards, such as those set by the International Electrotechnical Commission (IEC), and are manufactured with high-quality materials. Complying with these standards is essentially more than just complying with regulations; it is about ensuring that each device provides maximum safety.

Higher strength, longer life

Durability and reliability are indirect but important aspects of safety, and the right DC MCB can be designed to wear less and remain protective for longer. Performance reliability guarantees that DC miniature circuit breakers will work properly in the critical situation of long-term operation of electrical equipment.

Energy Efficiency and Savings

Besides being essential for protecting circuits, they are also a big factor in energy conservation, saving users money, such as the DC miniature circuit breakers (MCBs) currently produced by the company. These devices also feature energy-saving features that reduce operating costs and reduce environmental impact.

Low-energy design

In addition, these are the latest DC miniature circuit breakers that are designed to operate without wasting energy. San Francisco, California—High-quality materials and advanced manufacturing techniques combine to give these circuit breakers superior conductivity and reduced resistance. This design is more optimized, reducing energy losses by 5% compared to older models, thereby improving the efficiency of the entire system.

Impact on electricity bills

Combined with smart grid technology, DC miniature circuit breakers can help save thousands of dollars per year on electricity bills by reducing the use of phantom or standby power. On a larger scale, for industrial plants, the savings can be as high as several thousand dollars per year, depending on the size and complexity of the electrical system.

Extended component life

By controlling the flow of current, DC MCBs prevent stress and damage from overcurrent conditions, thereby extending the life of electrical equipment. With ease of use and proper maintenance, the life of equipment connected to the circuit breaker can be extended by 15-20%, reducing unexpected and catastrophic equipment failures and the associated repair and replacement costs.

Renewable Energy System Integration

DC MCBs play a huge role in renewable energy systems such as solar panels and wind turbine systems, … … They allow energy to be distributed and utilized in an output manner without any energy being wasted. This allows them to cut and make circuits, making the transmission and conversion of energy more efficient because less energy is wasted.

Regulatory Compliance Incentives

Energy-efficient DC MCBs comply with international energy standards such as the EU’s Energy Efficiency Directive (EED) or the U.S. Department of Energy (DOE). Businesses that meet the requirements often qualify for energy credits or tax incentives, which can greatly mitigate the high upfront costs of these facilities.

Compatibility with Smart Technology

Most modern DC MCBs are designed with the latest technology so they can be remotely monitored and controlled when needed. This feature allows you to understand how and when you use electricity, allowing for better control of energy usage and further savings.

Environmental Impact

Ultimately, the efficiency of a DC MCB directly leads to a lower carbon footprint. This helps save energy and reduce the burden on power plants, while minimizing the emission of pollutants and reducing greenhouse gas emissions - in line with international trends in environmental sustainability.

Durability and Build Quality

Direct Current (DC) Miniature Circuit Breaker (MCB): Durability and build quality directly impact lifespan and reliability. It must also be able to operate reliably and for long periods of time, even under demanding electrical conditions.

Materials of Construction

Higher-grade DC MCBs are made of high-quality materials that can withstand the wear and tear caused by heavy electrical loads and exposure to the elements. Common contact materials are silver and silver alloys, which have high conductivity and low arc erosion properties. The housing is usually made of flame-retardant, impact-resistant thermoplastics (or in some cases, thermoset composites) that have excellent insulation and mechanical strength properties.

Durability Construction Features

Other design features are double-break contacts and encapsulated construction that prevents dust, moisture, etc. from entering the device. These features reduce failure rates to more than 30% of standard designs by keeping the internal mechanisms clean and working.

Manufacturing Quality Control

The most effective DC MCB manufacturers ensure strong, consistent quality control during production. The components undergo a series of rigorous behind-the-scenes electrical, mechanical, and thermoelastic tests. Products that pass these tests and have a failure rate of no more than 0.1% over their expected lifespan are highly resilient.

Global standards compliance

Some DC MCBs are certified according to international standards such as IEC/EN 60898-1 or UL 489. In addition to mandatory verification, they also demonstrate the circuit breaker's ability to operate under well-defined conditions, as well as compliance with world safety and quality parameters.

Ratings and reliability information

Users of DC MCBs in challenging industrial environments often rate the build quality as very high in their feedback. Lifespan data shows that high-quality MCBs can operate reliably for more than 20 years with minimal maintenance costs, which also helps to reduce the total cost of ownership.

Impact resistance and environmental tolerance.

Thus, DC MCBs for outdoor or harsh environmental conditions can be equipped with additional protection (UV-resistant labels, anti-corrosion coatings). These improvements allow the MCB to maintain its performance under high temperature, high humidity and corrosive atmospheric conditions.

Warranty and support

Finally, trust in the lifespan of a DC MCB is often demonstrated by the warranty provided by the manufacturer. These extended warranties, sometimes up to 15 years, highlight the manufacturer's confidence that its products are durable.

Easy Installation and Maintenance

Top-quality DC miniature circuit breakers (MCBs) are not only efficient and safe, but also easy to install and maintain. Streamlining these processes is crucial because it means less downtime, cuts labor overhead, and improves overall operational efficiency.

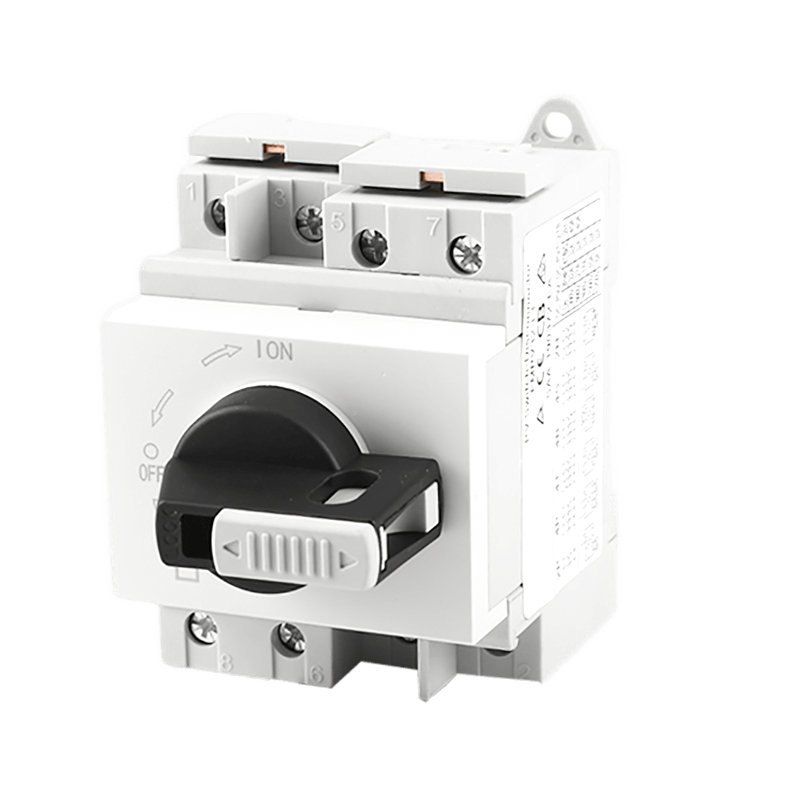

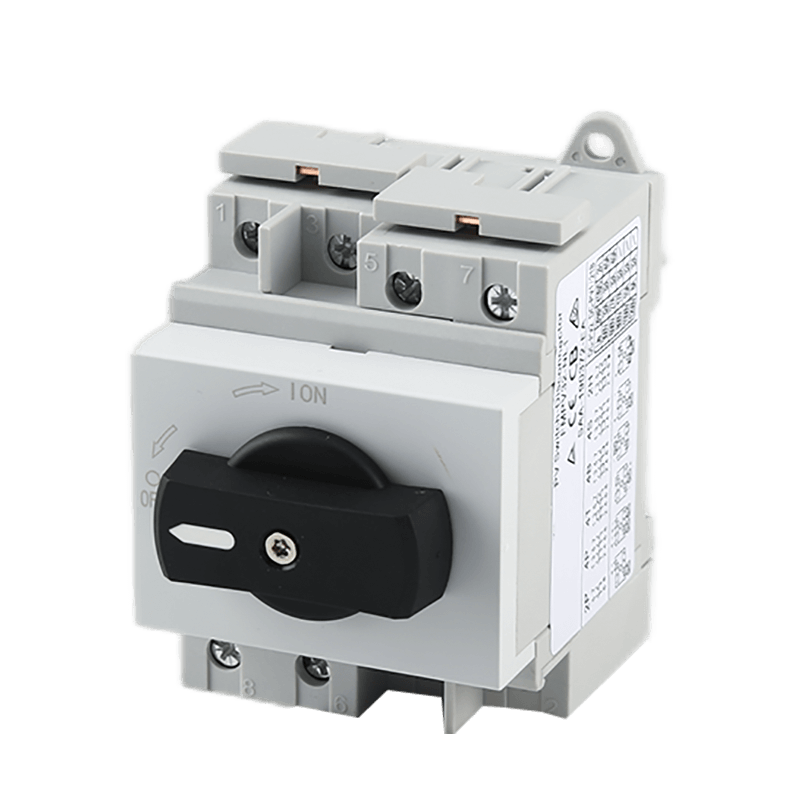

Modular design for quick installation

The best DC miniature circuit breakers are also quick and easy to install, thanks to their modular configuration. They are often available as part of a plug-in or snap-in system that can be mounted on a standard DIN rail without any special tools. This configuration significantly reduces installation time, in most cases by half compared to non-modular systems.

Color-coded and well-defined components

For accurate, cost-effective installation, quality DC miniature circuit breakers use color-coded terminal and component identification. This feature is extremely useful because it prevents installation faults, which are the root cause of most electrical defects. This is especially helpful in more complex setups using multiple circuit breakers.

User-friendly interface

A simple creation interface with step-by-step instructions and feedback helps improve ease of use. In fact, many new DC MCBs come with digital displays or LED indicators that quickly alert users to any issues with real-time status updates or diagnostics. Such feedback can immediately signal to the user where a problem may lie, reducing the need for extensive manual testing and making troubleshooting simpler.

Maintenance-Free Operation

Some DC MCBs, like the top models on our list, are designed to be maintenance-free. Rigorous construction and corrosion-resistant materials guarantee their longer durability and fewer inspections and replacements. Most MCBs can operate for years without any maintenance other than regular visual inspections and basic cleaning.

Standardization of Parts and Accessories

Standardized parts and accessories allow for hassle-free replacement and repair of DC MCBs – both of which are essential for increased safety and inherent in quality DC MCBs. It allows parts to be easily and inexpensively swapped for uniform inventory between models and batches.

Extensive Documentation and Support

Manufacturers of top DC MCBs provide comprehensive documentation, detailed installation guides, user manuals, and troubleshooting tips. Training and support are also provided regularly so that knowledgeable staff are informed and ready to assist with installation and maintenance.

Remote Monitoring Capabilities

DC MCBs with high-end features offer remote monitoring capabilities to ensure maintenance personnel can centrally monitor and track their performance and health. This enables operators to predict downtime by identifying faults before they occur, reducing unplanned downtime and costly disruptions to operations.