A mini circuit breaker (MCB) protects electrical circuits from damage by automatically cutting off power when detecting overloads or short circuits.

Introduction

Mini Circuit Breakers (MCBs) are an indispensable part of the electrical safe management of residential and commercial buildings. They are designed to automatically switch off electrical circuits in the event of an over-current, short circuit, or other abnormal condition, preventing fire, etc. MCBs can be reset, which is an advantage over the older fuse systems that have to be replaced every time they are blown and can lead to a significant cost saving over time.

The shift to Mini Circuit Breakers From Traditional Fuses

MCBs have a higher degree of accuracy in identifying fault conditions, which could certainly reduce the risk of electrical fires. If the statistics are anything to go by, then electrical fires have been the leading cause of residential fires id the United States over the years, most of it being from old sorts of protection like fuses. The installation of MCBs significantly improves electrical safety for homeowners as well as businesses.

Operational Mechanics of Mini Circuit Breakers

The thermal-magnetic trip mechanism of an MCB is at the core of it. This system enables the breaker to react to both continuous overloads (thermal) and short circuits (magnetic) with a quick disconnection of the electrical circuit. For instance, when a circuit overload is detected, the thermal device heats up and the heat causes the bimetallic strip to bend and pull the trip mech. For example, in severe short circuit conditions, the magnetic element will trip in response within a few milliseconds.

Benefits in Resetting and Reusability

A feature that sets MCBs apart from conventional fuses is that they can be reset after tripping. This reusability saves significant cost of replacements and reduces downtime to electrical service as well. While an MCB will go from the tripped position back to the ON position with the simple task of turning the lever back up again, this will leave the fault conditions in the system uncorrected.

Selecting the Right Mini Circuit Breaker

This requires a detailed know-how of what the system of protection that the MCB will be intended for. Selection of the switching power supply depends on factors such as maximum current load rating of the power supply, type of load (resistive, inductive) and environmental conditions. For example, a house needs a lesser capacity MCB than a factory where heavy machines work.

Working Principle of Mini Circuit Breakers

MCBs are devices that provide short-circuit and overload protection to your home electrical circuit. They operate using a dual technology of detecting thermal (overloads) and magnetic (short circuits) functions.

Thermal Tripping Mechanism

MCB Thermal Tripping In MCB, the thermal tripping function is achieved with the help of a bimetallic strip. A bimetallic strip is made using two different types of metals having different thermal expansion rates. This strip then carries the current in the circuit normally. But on an over current condition where the current exceeds the set limit for a considerable amount of time, the extra heat generated causes the strip to expand more on one side. It comes in contact with coolant, the top side expands more than the bottom side, and the strip curls, over time moving out of alignment enough to cause the circuit to break and the current to stop flowing. This device purposely responds very slowly such that only long term overloads will make it trip.

Magnetic Tripping Mechanism

For fatal threats such as short circuits, the MCB just utilizes a magnetic tripper, which works to prevail upon the other establishing conditions by electromagnetic acceptance. A rapid rise in current produces a magnetic field that is large enough to pull a solenoid inside the breaker. Within milliseconds, this solenoid will rapidly pull an armature to break the circuit, ensuring the surge of high current does not short any circuit boards. It is also critical when excess current could result in damage to electrical equipment or wiring they are designed to protect.

Combined Safety Features

MCBs provide protection from different kinds of electrical faults by incorporating both thermal and magnetic tripping mechanisms. They're essentially designed to trip at various maximum currents, ranging from anywhere between 6 to 63 amps depending on the MCB, and are suited for distinct purposes in a home or an industrial setting based on the power load. Not only does this two-fold efficiency greatly boosts safety but also shortens the likelihood of failures on the electrical aspects of the vehicle, which in return can manage and also attribute power in a more safe and hedged way.

Resetting the Breaker

The simplest thing to do when one MCB has tripped is to reset it. The first step is to make sure that the overload or the short circuit happened for a reason, and that the reason is gone now. Push the MCB lever/switch back into the on position to reconnect the circuit. Coupled with the accuracy, the capability of resetting and the rapid speed in activation of safety functions makes MCBs better than the traditional fuse systems, which have to be replaced after they trip.

Types of Mini Circuit Breakers

While categorization of MCBs are done based on the number of poles, or the number of circuits they can protect at a time. These types cater to different configurations and applications, guaranteeing safety throughout different electrical systems.

Single Pole MCBs

Take a look at single pole MCBs in use at homes This protects a single circuit and is intended for regular consumer-level domestic loads. These are the type of breakers that interrupt a single phase (live wire) and generally these are used on lighting and socket circuits. Typically, they have ratings of between 6 and 63 amps, depending on the load it is expected to carry and the need of the application. An example is a 10-amp MCB used for an average domestic lighting circuit, and a 32-amp MCB used for an electric stove.

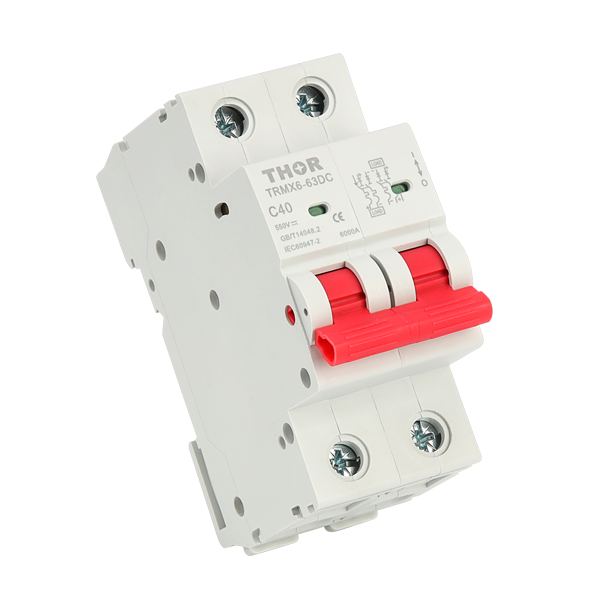

Double Pole MCBs

For protection where the fault can effect the grounded/neutral line and both the lines need to be tripped off simultaneously, double pole MCBs are used. Those are needed in systems where the neutral cab carrying current related to large appliances like: ovens, dryers,...etc This type of breaker can offer 30 to 100 amperes while break both the live and neutral connection, it usually accommodates larger appliances.

Three Pole and Four Pole MCBs

Three-phase MCBs come in 3-pole MCB types for electrical circuits and distribution boards with three-phase systems usually found in industrial environments. It guards three live wires at the same time, necessary for 3-phase systems used in heavy devices and business tools. These breakers disconnect all three phasses if one of the phasses has a fault, to avoid damaging equipment by giving a partial supply.

In addition to the three phases, four pole MCBs also offer protection for the neutral line. These are especially critical for applications in complex and sensitive industrial areas for which small deviation in the neutral could result in large disturbances or dangers.

Specialty MCBs

Specialized MCBs also exist for specific applications, such as those for DC circuits. DC current behaves very differently under fault conditions compared to AC systems and hence require differently designed breakers. In contrast, DC breakers have to extinguish an electric arc that is created from the disconnection of the circuit, which can be more difficult to do than in AC circuits, as an example.

Advantages of Using Mini Circuit Breakers

Miniature circuit breakers offer numerous advantages over convectional fuse-based systems that make it an excellent choice for safety of modern electrical equipment. MCBs provide a holistic approach to taming electrical hazards, offering a host of benefits from reinforced protection functions to usability and reliability.

Enhanced Safety Features

MCBs allow accurate, dependable protection in case of an overload or a short circuit, which are crucial to assist in lessening dangers such as an electrical fire, and reduce damages to valuable connected equipment. MCBs break the circuit quickly in case of a fault, hence prevent fire and limit damage to electrical equipment. The newer technology has several immediate benefits: an MCB can respond to a short circuit in milliseconds (magnetic trip feature), thereby avoiding high-current damage in a way that MMCBs and MPCBs cannot.

Economical and Reuseful

MCBs can be reset after a trip, which is not in the case of fuses that need to be replaced with a new one after it has blown. This not only reduces waste of materials but also significantly reduces the lifetime costs associated with circuit protection. Throughout the life cycle of an electrical installation, the ability to reset it, rather than replace it, can never be underestimated, and can often be the difference between literally thousands of dollars and hours versus less expensive maintenance costs, specifically within environments which are more prone to electrical issues.

Ease of Maintenance and Troubleshooting

MCBs are designed in such a way that helps in the fast detection and rectification of electrical problems. A status indicator (On, Off, or tripped due to a fault) is shown on each MCB, making troubleshooting easier, and downtime can be reduced. This feature helps the maintenance personnel in multi-circuit and complex systems in getting the circuit for which the MCB has tripped in a speedy manner for apt rectification.

Environmentally Friendly

MCB eliminates one time use fuses, e-Waste trend decrease due to this concept. These chuck-in-use for long time, and these can used several number of time, ultimately it is more sustainable and eco friendly way to used, as world wide are trying to reduce adverse impact of electrical items too.

Adaptability and Versatility

MCBs are available in different ratings and sizes, which makes them suitable for residential application to industrial application. These can be chosen to suit the nature of the specific electrical system, and provide the most benefit to the particular circuit they are protecting.

Installation and Maintenance

For a thorough protection of electrical circuits mini circuit breakers (MCBs) should be installed and maintained correctly. If these chores are done well, it ensures that the MCB can work at their best level and prevent the possibility of electrical error.

Installation Guidelines

MCB installations should only be performed by a trained electrician to reduce your risk of being electrocuted or breaking an electrical code. The process involves a few very essential steps, those are :

- Use the Right MCB: Opt only for an MCB that has the appropriate amperage according to the circuit that it will provide protection to. Usually, this is based on the worst case load that the circuit is expected to carry.

- Turn off the Main Power: Now you must turn off the main power of the house since you will be working with electricity and it is dangerous if the power is on.

- Fit the MCB on the Distribution Board: The MCB should be fit in the right slot on the distribution board. Make the connections tight to prevent any arcing or overheated.

- Connect the Circuit Wires: Connect the circuit live wire to the terminal to take current from the circuit where the MCB switch is connected and the other end towards the load. Make sure the connections are tight and properly covered.

- Check the Installation: When the MCB is fitted back, supply power and check the circuit to verify the operation of the MCB To do this we simulate a fault in the circuit to determine if the MCB trips accordingly.

Maintenance Best Practices

For the previous section that explained the importance of MCBs, the same rule applies in ensuring the equipment remains in a good state to be able to function appropriately. FixGrad is an expert in the maintenance of MCBs so you can also hire them in such a requirement. Maintenance usually includes:

- Visual appearance: MCBs should regularly inspect the MCBs visually for any signs of damage or wear. Inspect for discoloration (overheating), and verify that all terminal locations are secure.

- Test Tripping Mechanism: Always test the tripping mechanism frequently by pressing the test button on the MCB. This way the tripper can still trip if there is an overload or a fault.

- Cleanliness: Ensure that the MCB and its vicinity are clean and free from dust. A buildup of dust will hinder the performance of the breaker and can cause overheating.

- Corrosion: Examine the terminals and metal parts for signs of corrosion. This contributes to increased metal corrosion and poor conductivity that can result in the tripping of short-circuits.

- Documentation: Provide a record of all maintenance performed that includes any and all testing or inspections. This record can be useful in debugging future problems, as well as for regulatory compliance.