Ceramic gas discharge tube

Ceramic gas discharge tube is the most widely used switching device in lightning protection equipment. Gas discharge tube (GDT) uses metallized ceramic tubes and two or more electrodes to seal one or more discharge gaps. Inert gas is filled inside the ceramic gas discharge tube, and active electron powder is coated on the effective electron emission surface of the electrodes. The distance between electrodes less than 1mm can ensure the stability of the breakdown voltage of the discharge tube. The ceramic gas discharge tube is cylindrical in shape and has two structural forms with and without leads. Ceramic gas discharge tubes are used in communication or signal circuits with AC not exceeding 1200V and DC not exceeding 1500V, especially in the protection of information and signal systems. The tube is filled with an inert gas with stable electrical properties, such as argon and neon.

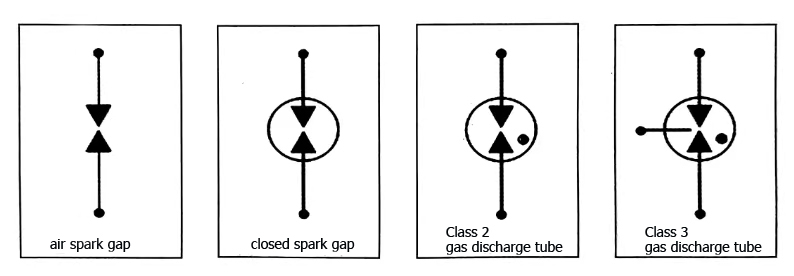

The following figure shows the circuit symbols of the gas discharge tube under different conditions.

When the voltage across the gas discharge tube reaches its DC discharge voltage, the internal gas breaks down and discharges. The volt-ampere characteristic of the gas discharge tube is nonlinear, and the breakdown process is divided into three stages: the DC resistance remains above 10°Ω before breakdown; the impedance and tube voltage drop drop sharply at the moment of breakdown, and the conduction current is severe Rise; Impedance and tube voltage drop remain at a very low level immediately after the breakdown, and continue until the voltage on the line is lower than the arc voltage of the gas discharge tube, and then return to the open circuit state by itself.

gas discharge tube circuit symbol